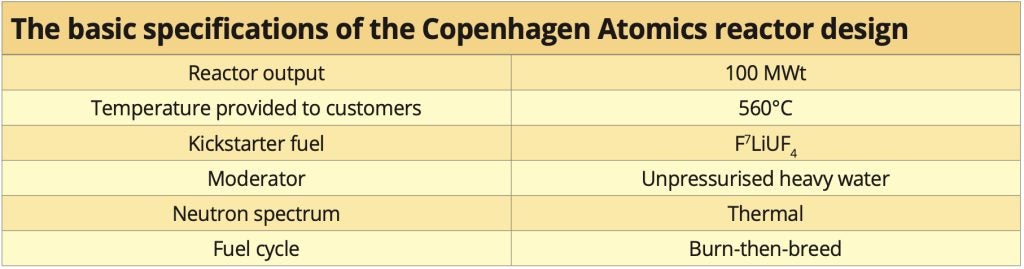

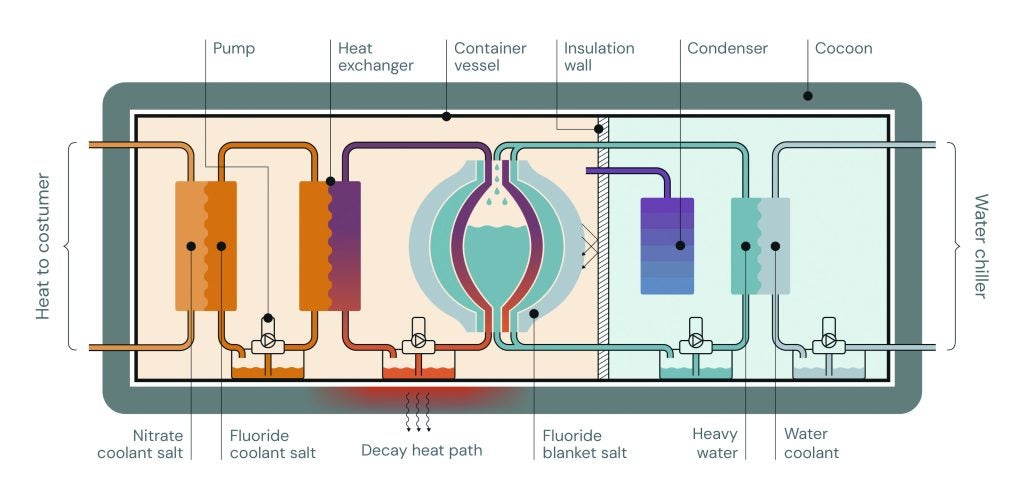

The technology being developed by Copenhagen Atomics is a heavy water moderated thorium molten salt reactor built into a 40-foot container, manufactured in a similar way to how cars are produced today. The plan is to mass manufacture the reactors on an assembly line, with an output of one reactor per day per assembly line.

The output per reactor is 100 MW thermal and the idea is to put them together like Lego bricks for large deployments. This makes the technology suitable for power production and other applications like process heat for industrial use, including production of hydrogen and green ammonia.

The technology is expected to reach an electricity price (LCoE) below $20/MWh in a mass manufacturing scenario. Copenhagen Atomics is also planning an “energy-as-a-service” business model, where it will build, own, operate and decommission the thorium reactor, with no investment required by the customer, and no need for taxpayer investments.

As an extra benefit the thorium reactor can utilise spent fuel from conventional nuclear power plants (thereby reducing the storage time from 100 000 years to 300 years). For this reason, the technology is called a waste burner.

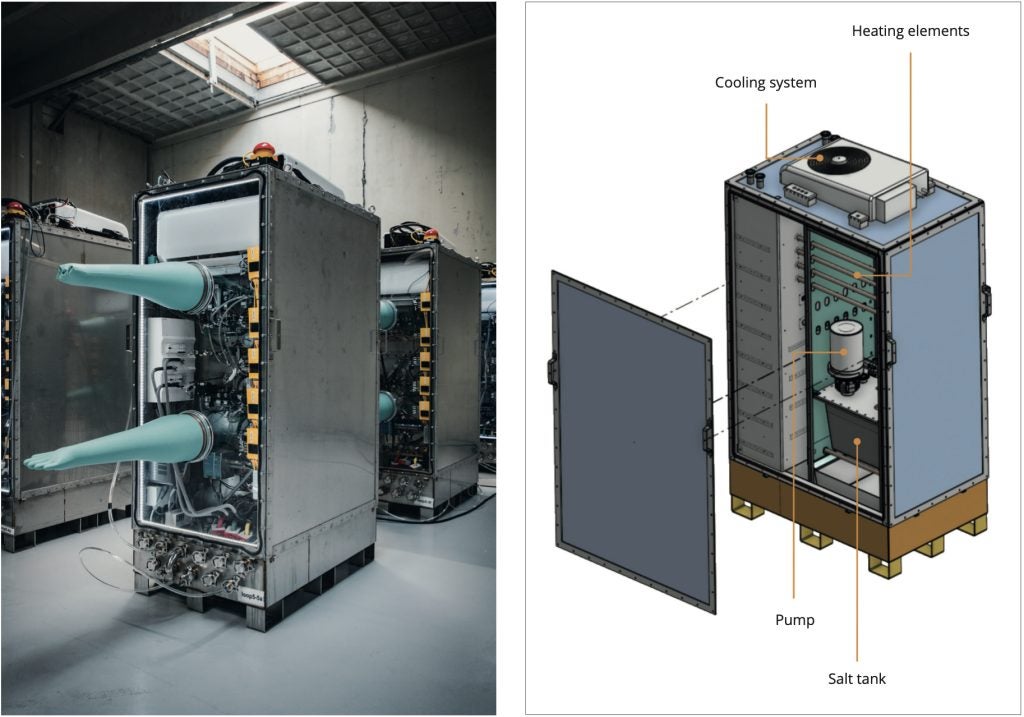

Copenhagen Atomics is a “product-first” company and has already built and is operating its first full size non-fission prototype, running at 600°C. To get to this point extensive R&D and testing has been carried out in support of achieving this major milestone, in accordance with an aggressive roadmap that calls for a commercial launch by 2028.

The “product-first” approach has been pioneered by companies like Tesla and SpaceX, and Copenhagen Atomics subscribes to the same concept: build; test; refine; and harden technology for success.

The world is in dire need of extra power generation capacity while reducing, eventually eliminating, emissions. The only way to do this is by adopting innovations from many avenues. The company believes that thorium molten salt technology can make a significant contribution to the transformation of the global energy system and one scenario suggests that the energy output of thorium reactors in 40 years time could be similar to that of gas today.

So how did this all come about…? The foundation and origin was the MSRE (Molten Salt Reactor Experiment), a thorium breeder reactor that ran for five years back in the 1960s at the Oak Ridge National Laboratory (USA). As the internet gained traction around 2000 the IP behind this technology was made available, and it was picked up by many university groups around the world. That was how the resurgence of interest in molten salt reactors first started, leading to an industry that is currently emerging.

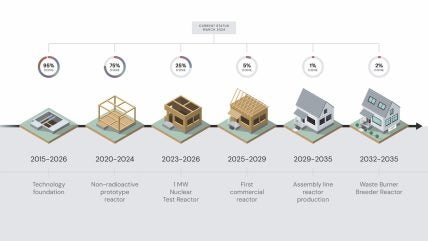

Six milestones

Copenhagen Atomics has defined six milestones (see image opposite) that underpin and characterise the company, from inception to the end-game of building a breeder reactor that will supply cheap, abundant energy for potentially thousands of years going forward.

Milestone #1. Copenhagen Atomics has been working on the first milestone since 2014, having obtained several valuable patents and developed new methods and products that did not exist before. The company also makes some of these innovations available for sale to others (eg molten salt test loop technology and highly purified salts), as part of a win-win collaboration, with Copenhagen Atomics receiving data from fellow molten salt researchers.

The components can still be improved, but Milestone #1 is considered 95% complete.

Milestone #2 is currently 75% complete. Two non-fission full-scale reactor prototypes have been built, and the company is in the process of ordering the third. The third reactor will be tested with thorium and uranium salts at 600°C.

Milestone #3 involves a 1 MWt demonstration/test reactor with the goal of proving the ability to build and operate a molten salt reactor with a thorium blanket — a feat never accomplished before.

The test reactor is expected to run for a 30-day cycle towards a regulatory approval in a country with nuclear experience and has all the features of a commercial reactor, in scaled down form. The test reactor is necessary to prove the accuracy of the simulations as well as material, production methods and volatile fission product removal. The focus for the next two years will be on achieving Milestone #3, drawing on the extensive experience gained from over 140 years of test time in attaining Milestone #2.

Current build of a non-fission prototype for the 1 MWt demo reactor will validate the reactor design using a non-nuclear fuel salt, and this is expected to be an operational demo reactor ready by 2025.

Milestone #4 is expected to be relatively straightforward after achieving Milestone #3, although running several versions of test reactors may be necessary before constructing five to ten commercial reactors. The aim is to have commercial reactors available by 2028, pending approval from countries ready to endorse such advanced reactors. Assembly of the ten commercial reactors is planned at the current company headquarters.

This sets the stage for Milestone #5, involving assembly line production of reactors and rapid installation at a small number of sites. Copenhagen Atomics will establish assembly line production in a “Giga-factory” setting, receiving components from hundreds of sub-suppliers and assembling reactors in sequence, with a shipment of one reactor per day. Each assembly line requires approximately 1000 people, and it should be possible to install 15 GWe of the new reactors per year. Giga-factories are likely to be located in the countries that first approve type certifications and allow fast deployment of the reactors.

Milestone #6 is considered the most exciting as achieving a breeder reactor in the thermal spectrum can be likened to the first moon landing. This milestone holds the potential to unlock an energy source surpassing fossil fuels in both price and scaling capabilities.

While Milestone #6 may seem distant, with a potential achievement date of 2035, the progress made in the last ten years has brought Copenhagen Atomics closer to its goals. The year 2024 is anticipated to be particularly exciting for the company, marked by non-fission reactor tests, lithium 7 production, and large-scale uranium and thorium salt production and handling.

Copenhagen Atomics is currently actively working on fundraising to advance this roadmap and is actively having conversations about a host country for the test reactor. One of these conversations is with the UK, which already has a long history of nuclear technology and extensive nuclear infrastructure.

Copenhagen Atomics did not enter the GDA (Generic Design Assessment) process in the UK since it was not suited to this initiative. The scope of what Copenhagen Atomics wants to do is different from other Generic Design Assessment participants since what is envisaged is a small test reactor that only generates heat and not electricity. However, there are multiple conversations going on in the UK with the government, sites and the ONR (Office for Nuclear Regulation) to explore avenues towards approval of a test reactor.

Copenhagen Atomics also seeks to get the test reactor approved in other countries and there are conversations currently underway in a number of places with announcements expected soon.

Reaching such a hosting agreement should benefit both the host country, Copenhagen Atomics and the world at large.

The test reactor will pave the way towards a commercial launch. The pilot country for this technology is most likely to be the country that hosts the test reactor and will therefore be the first to get the benefits from a commercial deployment.

On the move

In 2023 Copenhagen Atomics closed an investment round of €25 million and this enabled the move to a new headquarters/test facility and towards growing the company into a global leader in nuclear energy. Copenhagen Atomics moved to the previous location at Alfa Laval in 2019 and this was a similar big step up from the basement at the Technical University of Denmark, where the company started. At Alfa Laval, there were real production facilities with overhead cranes, large machines and a canteen. However, the company had completely grown out of that location, and desperately needed more floor space for test and production. The new headquarters at Kastrup, close to Copenhagen airport, has an area of 11000 m2 and lots of space to grow into a real reactor company that delivers real commercial reactors.

At the new headquarters it is not possible to run chain reactions in real nuclear reactors, but it is possible to build full-scale non-fission prototypes and test them with thorium and uranium bearing salts using electrical heaters. Copenhagen Atomics will also run the world’s biggest thorium molten salt purification line and is now building the world’s biggest lithium 7 production line here.

Author: Jesper Glahn, Copenhagen Atomics