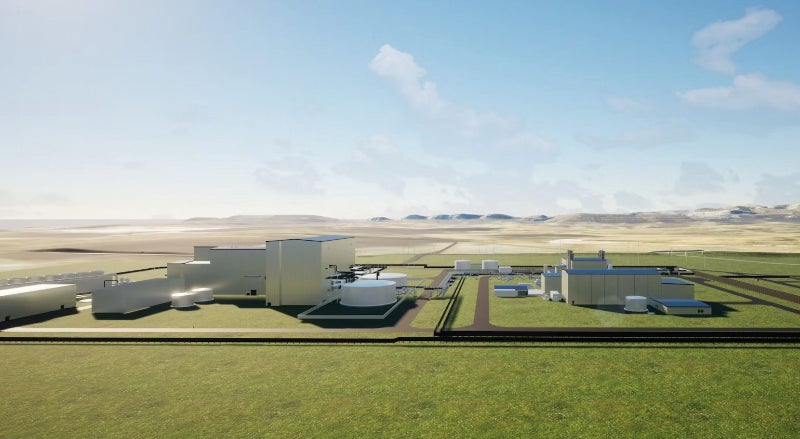

In June, start-up TerraPower celebrated the commencement of construction – albeit non-nuclear scope – on the Natrium reactor demonstration project, Kemmerer, Wyoming. This is the first of a new wave of advanced and small modular reactor projects at various stages of development in the USA to move from design into construction (with “advanced” essentially meaning not water cooled).

“This groundbreaking represents the beginning of the next era of nuclear energy. The Natrium reactor is more than a design, it’s a plant coming to life that will support both the clean energy transition and our historic energy communities,” said Chris Levesque, TerraPower President and CEO.

TerraPower Chairman and Founder, Bill Gates, said “I’m proud of all the partners and people who helped get the most advanced nuclear project in the world built in Kemmerer, Wyoming. I believe that TerraPower’s next-generation nuclear energy will power the future of our nation—and the world.”

The project also demonstrates how “good things can happen when the private and public sectors work together to solve problems,” said Wyoming Governor Mark Gordon.

Upon completion, the Natrium plant, aka Kemmerer 1, although classified as a demonstration facility, will be “a fully functioning commercial power plant,” says TerraPower. It is being constructed on a site purchased from PacifiCorp near a retiring coal-fired power plant (Naughton) and is said to be “the only coal-to-nuclear project under development in the world.”

Natrium, based on GE-Hitachi’s Prism concept, which can trace its antecedents back to the beginnings of nuclear power generation, EBR 1 (the first nuclear reactor to generate electricity), EBR 2 and S2G (employed in the Seawolf nuclear submarine in 1953 but subsequently replaced with a PWR). It is a 345 MWe (840 MWt) sodium-cooled fast reactor with a molten-salt-based heat transfer and energy storage system. The storage technology can boost the system’s output to 500 MW [for 5.5 hours] when needed, allowing “the plant to integrate seamlessly with renewable resources,” says TerraPower, noting that it is “the only advanced reactor design with this unique feature.”

TerraPower submitted its construction permit application for the Natrium reactor to the US Nuclear Regulatory Commission (NRC) in March 2024, the first such application for a commercial advanced reactor to be submitted to the NRC, says TerraPower. “Due to its unique design”, non-nuclear construction was able to start, “while nuclear construction will begin after this application is approved.” The plant could enter operation potentially by about 2030.

“With the separation of major structures into a ‘nuclear island’ and ‘energy island’, the Natrium plant requires less nuclear-grade safety equipment and is designed to utilise construction material quantities that are comparable to a combined cycle plant and significantly less than other reactor designs,” suggests TerraPower.

Through the US DOE’s Advanced Reactor Demonstration Program (ARDP), a public–private partnership, the Kemmerer project “is intended to validate the design, construction and operational features of the Natrium technology.”

ARDP authorises a 50/50 cost share and up to $2 billion for the Natrium project. TerraPower and partners will match this investment dollar for dollar. The first-of-a-kind cost for the Natrium demonstration plant will include the reactor design and licensing, codes and methods development, fuel development and qualification, and the design, construction and operation of two supporting facilities: the Natrium Fuel Fabrication Facility and Sodium Test and Fill Facility. The sodium facility will be used to test and demonstrate the performance of first-of-a-kind equipment prior to operations in the reactor plant.

TerraPower was founded some 16 years ago by Bill Gates and a group of “like-minded visionaries” that decided the private sector needed to act in developing advanced nuclear energy “to meet growing electricity needs, mitigate climate change, and lift billions out of poverty.”

An expert group of scientists and engineers was formed to analyse all energy generation technology options from a total systems perspective.

After a thorough examination of all known and “some heretofore unknown” reactor concepts, including lead-cooled reactors and small modular helium-cooled reactors, TerraPower decided to focus development on improving the sodium-cooled reactor design that met all of the stated objectives of TerraPower’s founding principles. TerraPower then embarked on the half-billion-dollar development programme which is still underway.

In 2019, TerraPower and GE-Hitachi joined forces to develop the Natrium technology. Partners include EPC contractor Bechtel and utilities Energy Northwest, Duke Energy, PacifiCorp and Rocky Mountain Power (subsidiary of Pacificorp). (Interestingly, back in the early 1960s, Bechtel built the Naughton power station that is now being retired, originally constructed as a “mine mouth powerhouse” for a coal strip-mining operation.)

The Natrium reactor employs high-assay, low-enriched uranium (HALEU) metallic fuel and aims to take advantage of the simple and robust safety profile of sodium cooled fast reactors to dramatically reduce the complexities associated with nuclear design and construction, including avoidance of complex containment structures and maximum use of inherent safety features. Safety functions are made integral to the reactor vessel, and support equipment is moved to separate structures with reduced requirements, resulting in a vastly simplified reactor building. The superior heat transfer characteristics of sodium and operation at low pressure permit the use of compact and lightweight equipment, unlike in other reactor types cooled with pressurised water or gas.

The Natrium reactor is coupled to what is called an Integrated Energy System (IES), the molten salt loop that transports heat from the nuclear island to the energy island. This minimises the amount of high-cost equipment and structures on the nuclear site and enables load following, coupling to thermal energy storage, and industrial heat applications (making use 500°C heat output). Use of molten salt technology aims to reduce cost and eliminates the difficulties of managing the sodium-to-steam heat transfer interface.

According to TerraPower, the higher operating temperature and constant thermal output make Natrium an ideal match for thermal energy storage using molten salt, a technology that is commercially deployed in the solar industry. Hot sodium from the reactor transfers its heat to the molten salt loop, which carries heat off the nuclear site where it can be stored, converted into electricity, or used for industrial process heating. This “decoupled” architecture minimises the size of the nuclear site and allows the reactor to operate at constant conditions, while the energy island meets variable energy demands, TerraPower notes.

The Natrium project is aiming for a construction time of 36 months (nuclear concrete pour to fuel load) and is one of the first nuclear power projects to benefit from Bechtel’s suite of digital tools and systems, “which have been proven to deliver exceptional results on other large energy facilities.”

Contract awards announced to date for the Natrium project include the following:

- Sargent & Lundy: Kemmerer training centre design;

- Framatome: HALEU metallisation pilot plant; design of ex-vessel fuel handling machine and bottom loading transfer cask;

- GERB Vibration Control Systems: seismic isolation equipment;

- Thermal Engineering International: design and fabrication of the sodium–salt heat exchanger;

- Hayward Tyler: design, fabrication, testing and qualification of primary and intermediate sodium pumps;

- Teledyne Brown Engineering: design, fabrication, and testing of in-vessel fuel transfer machine;

- Western Service Corporation (WSC): software and engineering services for Natrium engineering simulator;

- James Fisher Technologies: injection casting furnace system;

- BWXT Canada: design of intermediate heat exchanger;

- Curtiss-Wright Flow Control Service, LLC: development of reactor protection system;

- Global Nuclear Fuel–Americas: fuel; and

- Centrus: development of commercial HALEU production in USA (original plan had been import from Russia).

Kairos begins Hermes construction

Meanwhile, at Oak Ridge, TN, Kairos Power (founded 2016) has started construction of its 35 MWt (heat only) Hermes Low-Power Demonstration Reactor, the first and only Gen IV reactor to be approved so far for construction by the US Nuclear Regulatory Commission and the first non-light-water reactor to be permitted in the USA in over 50 years. The NRC issued the construction permit in December 2023.

The fluoride-salt-cooled high-temperature reactor will make use of technologies that originated in Oak Ridge — a novel combination of TRISO coated particle fuel pebble bed technology and FLiBe molten fluoride salt coolant, which yields robust inherent safety while simplifying the reactor’s design. FLiBe is a chemically stable mixture of lithium fluoride (LiF) and beryllium fluoride (BeF2). It is both a nuclear reactor coolant and solvent for fertile or fissile material. It served both purposes in Alvin Weinberg’s Molten-Salt Reactor Experiment (MSRE) at the Oak Ridge National Laboratory in the late 60s.

Hermes’ primary objective is to demonstrate production of affordable nuclear heat. Aiming for operation in 2027, it is a joint effort by Kairos Power and its partners, including Oak Ridge National Laboratory, Idaho National Laboratory, EPRI, and Materion Corporation. In addition, Kairos Power is partnering with Los Alamos National Laboratory to produce TRISO pebble bed fuel for Hermes in the lab’s Low-Enriched Fuel Fabrication Facility. Kairos Power has also established a co-operative development agreement with the Tennessee Valley Authority to provide engineering, operations, and licensing support for Hermes.

Barnard has been contracted to perform site work. In tandem with Hermes, Barnard and Kairos have also started collaborating to build the third Engineering Test Unit (ETU 3.0) — a non-nuclear demonstration co-located in Oak Ridge that will generate supply chain, construction, and operational experience to inform the Hermes project. This iterative approach will allow lessons learned from ETU 3.0 civil construction to transfer seamlessly to the Hermes facility, says Kairos.

Rising from the footprint of the historic Oak Ridge Gaseous Diffusion Plant, the project will continue the region’s distinguished nuclear legacy and promote its resurgence as a hub for advanced nuclear innovation, Kairos believes.

Kairos Power has committed to invest at least $100 million, while the US Department of Energy will invest up to $303 million in the project through a performance-based milestone contract funded by the Advanced Reactor Demonstration Program.