Air-cooled condensers (ACCs) use ambient air to condense turbine exhaust steam, eliminating the need for water cooling.

The systems use a series of large motor-driven fans to force air over finned tubes, cooling the steam and converting it into condensate, which is returned to the boiler. Removing water from the equation allows for more flexibility in locating plants and addresses concerns around using water as a resource – which can be costly to treat.

However, the challenges facing this cooling method are many and varied, according to Gary Dicker, UK, European, and Middle Eastern cooling specialist at Galebreaker.

“When wind disrupts ACC operations, it can cause significant mechanical and thermal inefficiencies.”

“One of the main issues we see is wind shear, which destabilises the airflow and causes imbalances across the fan cells. This results in mechanical stress, particularly on fan blades, which can lead to increased vibration and eventual component failure. Additionally, poor airflow reduces the cooling efficiency and can be a cause of hot air recirculation,” he says.

For plant managers, this drop in performance often leads to de-rating, meaning the plant operates below its designed capacity, directly impacting power output and creating lost revenue. In some cases, the financial cost of reduced ACC performance can be severe, with plants forced to burn more fuel to compensate for lost power generation, or even temporarily shut down to protect equipment, creating further losses or incurring financial penalties.

Why windscreens?

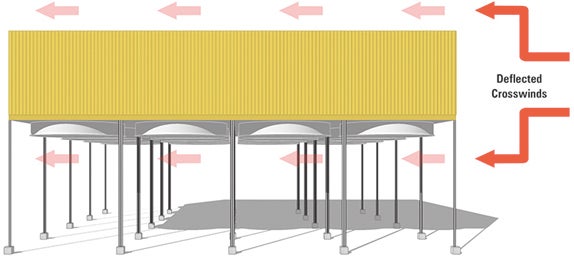

“Wind is an air thief, stealing air away from where the condenser needs it most,” says Gary. “By moderating the wind’s speed and redirecting its flow, windscreens counter this effect, stabilising airflow and ensuring the condenser can access the air it needs for optimal performance.

“The screens act as a barrier, slowing down crosswinds and stabilising air underneath the fan, allowing the ACC to use the air more effectively for cooling, while also reducing mechanical vibration.”

“The focus is to provide stability and consistent operation. The windscreen’s main objective is to protect performance by mitigating wind issues; not necessarily to increase output beyond original design levels,” he explains.

One of the key advantages of windscreens is their adaptability and cost-effectiveness as a retrofit solution. “Wind issue mitigation is not always considered during the design phase,” says Gary. “Add to that the fact that many power plants face spatial or planning restrictions that dictate where they are located. Operational budgets may further limit design modifications after construction.”

“We can’t control the ambient temperature or wind speed, but we can influence how wind interacts with the plant’s components. Windscreens offer a flexible, non-intrusive solution – often installed using simple ratchet and strap fastenings, attached to existing infrastructure. This makes them a cost-effective alternative to structural changes,” says Gary.

“They’re composed of a mesh fabric, making them lightweight but durable. The best engineered solutions can last upwards of 20 years, as we’ve seen with the screens at Coryton power station in the UK. Typical payback periods for the screens range between four to 12 months.”

The role of CFD modelling

Computational fluid dynamics (CFD) modelling is at the heart of windscreen placement optimisation, providing an evidence-based approach to enhancing ACC performance.

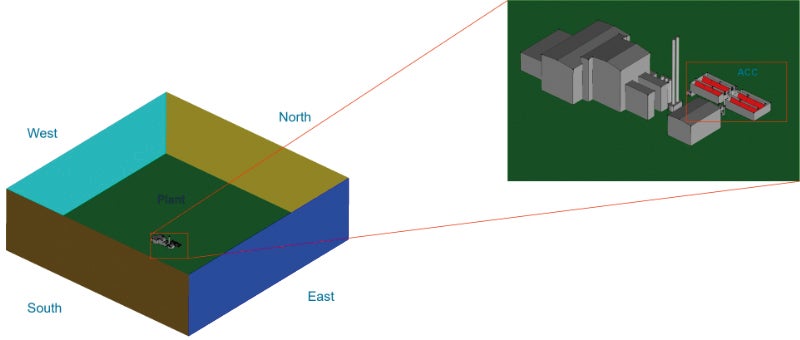

By virtually recreating a plant’s layout, CFD analysis allows engineers to test how wind flows around the surfaces and structures of a plant, determining how it will impact ACC efficiency. “CFD has been transformative,” Gary says. “It helps us identify where windscreens should be placed to stabilise airflow around the fans, to maintain efficiency and protect mechanical components.”

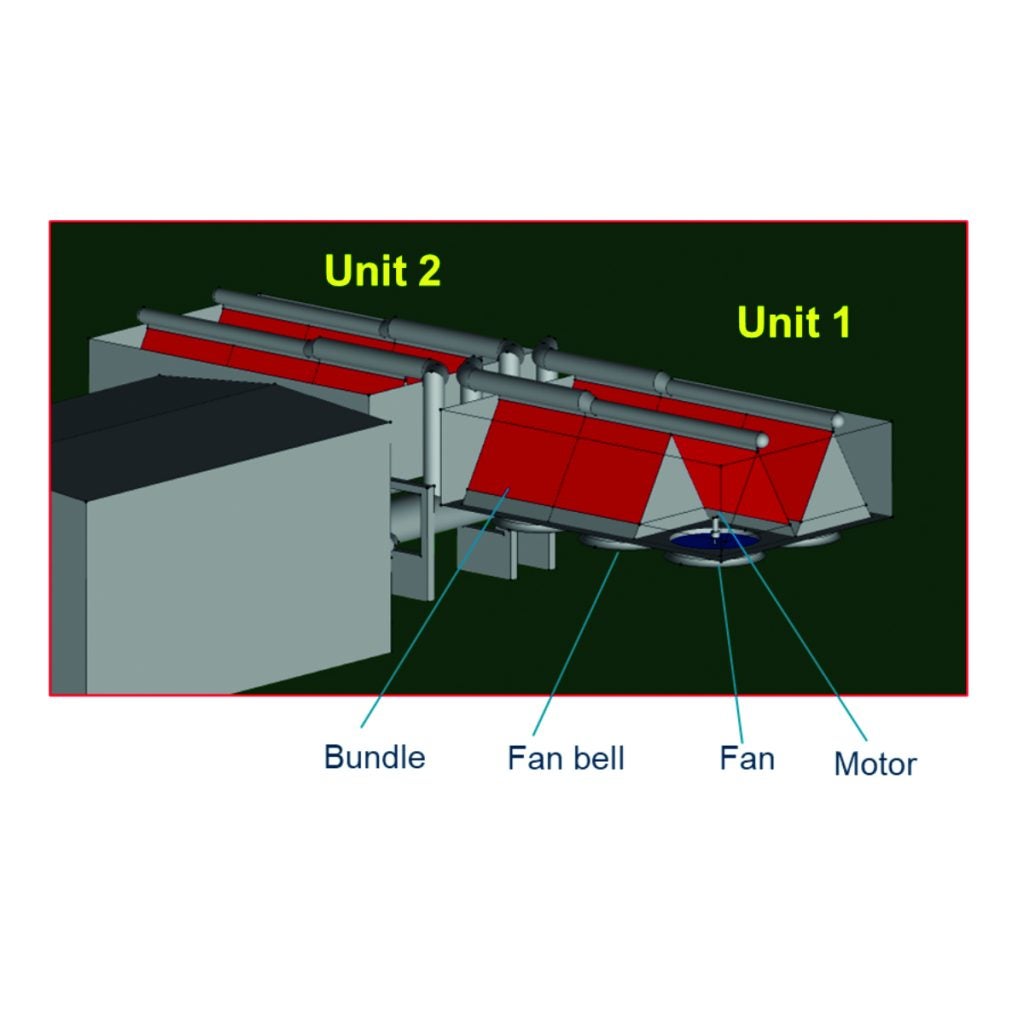

Through this modelling, Galebreaker has learned that a dual windscreen approach — incorporating both perimeter and cruciform screens — delivers the best results. “Initially, the focus was on top-mounted screens to mitigate wind shear. However, it became clear that while these screens reduced mechanical vibrations, they had a lower impact on increasing thermal performance than the cruciform screens, which sit in a cross-formation beneath the fans to ensure better airflow, reducing the risk of recirculation and interference.”

The processing of CFD results using this ‘digital twin’ approach allows a detailed analysis of how plant managers can expect windscreens to impact performance. “By applying typical wind conditions to the model, we can calculate the effect on steam back pressure and megawatt output. Translating these performance gains into financial projections enables us to calculate the payback period for plant managers, helping them justify the investment.”

Insights from the ACC Users Group conference

The Air-Cooled Condenser Users Group – the only professional member network dedicated to resolving issues with air-cooled condensers, held their annual conference for the first time in the UK at the University of East London, in July 2024. Over three days, leading suppliers, industry professionals and consultants gathered to exchange insights on best practices and strategies for optimising ACCs, focusing on the complexities of ACC operations in different environments. Below, two delegates share their experience of how windscreens have improved their plant operations.

Overcoming wind challenges at enfinium’s Ferrybridge 1 plant

enfinium’s Ferrybridge 1 is a waste to energy (WtE) facility in Knottingley, West Yorkshire, UK, with a generating capacity of up to 85 MW (gross). The plant processes around 725 000 tonnes of residual waste per year.

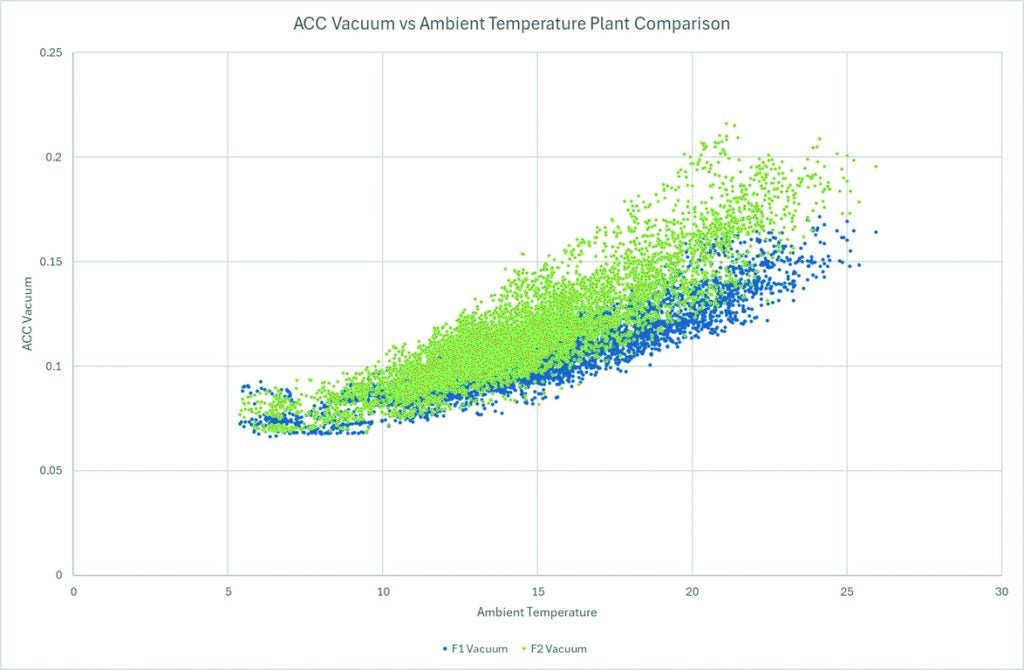

Lee Rhodes took over as operations manager at Ferrybridge in 2022 and immediately noticed performance issues. “During my first summer, I noticed we were experiencing thermal performance loss, and our ACC wasn’t operating at the levels expected. Despite regular cleaning and analysis confirming that our dissolved oxygen levels and steam mass flow were fine, our performance lagged behind our sister site, Ferrybridge 2,” Lee explains . “Ferrybridge 2 had more consistent backpressure even though our operating parameters were the same. That’s when we started to explore the impact of wind shear on our ACC – something I’d studied during my Master’s degree.”

“The positioning of Ferrybridge 1, combined with incoming south-westerly winds, meant wind shear was starving one street of our ACC fans,” Lee continues.

The knock-on effects were twofold: plant de-rating reduced power output, while the reduced boiler feed capacity slowed down the entire waste to energy process. “Not only were we losing generation on the backend, but it was also impacting the amount of feedstock we could process at the front end, causing a bottleneck in operations.”

Tackling the problem

Given the scale of the problem, enfinium sought a solution that would offer clear financial justification. For Lee, CFD modelling played a crucial role in the decision-making process. “CFD modelling was key in giving us the confidence to proceed,” Lee states. “We provided 12 months’ worth of weather data and detailed information on our plant layout to Galebreaker. From that, they created a digital twin of Ferrybridge 1, allowing us to test different configurations of perimeter and cruciform windscreens.”

The digital twin offered performance projections that were vital to justifying the capital outlay. “What was crucial for us was that the model could accurately show the thermal and mechanical benefit of the windscreens before committing to installation,” Lee explains. The results were clear: a payback period of just seven months was forecast based on increased megawatt output, translating into a financial benefit of £150 000.

Measurable improvements

Since the installation of the windscreens, Ferrybridge 1 has seen a marked improvement in performance. “The digital twin was pretty accurate in predicting the outcome,” Lee reflects. “Ferrybridge 1 is now consistently outperforming Ferrybridge 2, with a better backpressure rate. The windscreens have also helped reduce the strain on our fan motors and gearboxes, improving overall mechanical stability.”

“We also no longer have to adjust our boiler throughput rate or risk tripping the turbine due to high backpressure, something that happened in 2022, but hasn’t been an issue since,” he adds.

Looking ahead: wind and climate change

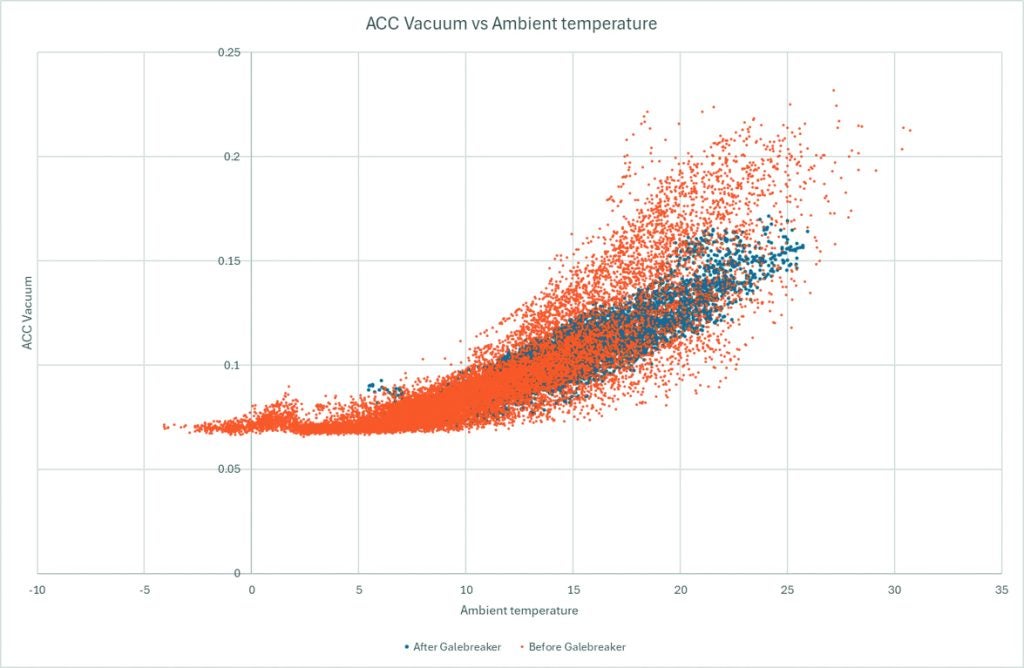

Lee predicts rising ambient temperatures, due to climate change, will make ACC performance more challenging, increasing the need for wind mitigation. “From autumn to spring, we’re seeing 80 to 100 MWh per day more generation at Ferrybridge compared to the summer,” he notes. “If you consider that at £100 per MWh, you’re looking at about £9000 per day loss potential because of higher ambient temperatures.”

With windscreens proving their worth, plans are now underway to install them at four sister sites, including the company’s new location at Skelton Grange. “It’s crucial plant managers monitor their ACC performance closely and address any deviations. Engaging with a specialist and using CFD modelling gives peace of mind that the investment will deliver a return in a short period.”

Fadhili combined heat and power plant – addressing ACC challenges in the desert

The Fadhili combined heat and power plant (FCHPP) is a 1507 MW gas-fired facility in Saudi Arabia’s Eastern Province. Co-owned by Engie Energy Services, Saudi Aramco, and Saudi Electricity Company, it plays a critical role in meeting the country’s growing energy demand.

FCHPP, commissioned in 2020, is located next to Saudi Aramco’s Fadhili gas plant, the first gas plant to treat non-associated gas from both onshore and offshore fields, with a processing capacity of 2.5 billion standard cubic feet per day (BSCFD). FCHPP is an integral part of the Saudi Aramco Fadhili gas plant as the plant is fully dependent on FCHPP for its 1447 tons per hour (TPH) process steam and 768 TPH feedwater supply.

Fadhili’s desert location poses severe challenges for its ACC system, explains Muhammad Asim Ghafoor, the plant’s lead performance and reliability engineer. “In the design, wind speeds up to 3 meters per second were assumed, but in reality we face gusts of up to 15 meters per second.

“The stronger-than-expected winds caused high vacuum levels, which led to de-loading during peak summer demand – resulting in financial penalties. Reduced load triggered gas flaring, as the plant couldn’t consume natural gas from the 40–50 km pipelines supplying it fast enough”.

The plant considered adiabatic cooling, but the high cost and lack of water made this solution unviable. “Adiabatic cooling was ruled out because it didn’t address the wind problem and required water, which is scarce in our region,” Muhammad notes. Instead, they opted for windscreens. “The windscreens were lightweight and manufactured to fit the existing steel frames of our ACC, which was a key factor in our decision.”

To ensure optimal windscreen placement, Galebreaker used CFD modelling, which gave the necessary assurances to the plant’s investors and shareholders. “The CFD analysis confirmed the screens’ effectiveness and allowed us to secure investment with confidence,” says Muhammad.

Since the installation of the windscreens in 2023, Fadhili has experienced dramatic improvements. The plant saw a rapid return on investment, achieving payback within just three months.

“In 2022, we were frequently reducing load almost on daily basis, but last summer, we only reduced load twice – and that was during the two hottest days of the year,” says Muhammad. “Moreover, gas flaring has been eliminated, reducing environmental impact and financial penalties.”

With water scarcity driving more plants in Saudi Arabia to adopt air-cooled condensers, Muhammad anticipates increased demand for windscreens. “We’re seeing more plants moving inland, away from coastal areas where they could rely on seawater cooling. As more plants transition to air-cooled condensers, wind mitigation will become a critical factor for stable plant operations,” he concludes.

Future developments

As climate conditions become more unpredictable, future demands will likely call for more advanced strategies.

Galebreaker is already exploring ways to enhance windscreen technology, including the potential integration of bespoke wetting systems to offer an alternative to traditional adiabatic cooling, addressing both temperature and wind issues.