As one of the most exposed parts of any turbine, blades in particular are susceptible to wear and damage which can significantly impact overall performance. Additionally, blades are the most challenging and expensive components to fix, with a single element replacement costing in the region of approximately $300 000 to $500 000.

Increasingly, many types of turbines are exhibiting blade failures, especially new designs, which might not have had as long a prototype testing stage as the industry was used to. Some of these failures have resulted in blade liberations, generating many headlines around the world and leaving asset owners with significant reputational damage.

Detecting faults at an early stage is essential for maintaining operational integrity, reducing maintenance costs, and extending the lifespan of these crucial assets.

Case study

During a recent project for a leading supermajor wind energy owner–operator

in the USA, ONYX Insight, a predictive analytics solution provider, found the owner-operator was experiencing issues with persistent blade root connection failures at one of its onshore wind farms, which has over a hundred 2 MW wind turbines. The failures were becoming a significant threat to the operational efficiency, safety and financial performance of the wind farm.

While existing measures provided some insights into the issue, they failed to deliver an adequate picture of asset health necessary for long-term management. In addition, the in-house temporary methods were a drain on valuable internal resources. The owner–operator drastically needed a more scalable, long-term solution, offering dependable data that could support a more proactive approach to maintenance planning.

ONYX Insight was therefore onboarded to deliver its ecoPITCH blade root connection monitoring system. The technology has a proven track-record in identifying faults, monitoring more than 1000 turbines to date.

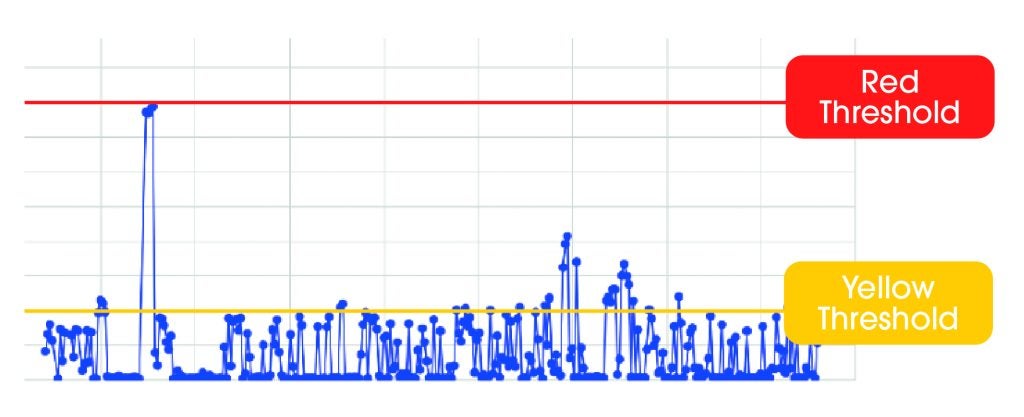

By combining the ecoPITCH data acquisition unit with fleetMONITOR predictive analytics software, potential failures can be identified up to 12 months in advance of bearing replacement, tracking damage progression along the way. Using sensors placed within the turbine, the condition monitoring hardware can transmit round-the-clock insights and data analytics, reducing the need for engineers to climb turbines and mitigating the risk of catastrophic failures, contributing to operations and maintenance cost savings.

Following installation, the predictive technology marked a paradigm shift in the detection and management of blade root connection issues at the wind farm. Initial findings from the system immediately identified that a significant portion of the turbines – between 10 and 20% – required rapid intervention.

Ultimately, this led to the owner-operator de-energising a number of turbines pending fixes, safeguarding their performance and integrity. The initial period of identifying already progressed blade root failures laid the groundwork for a predictive maintenance strategy ready to intercept and address new or escalating faults moving forward, ensuring the wind farm’s integrity and long-term performance.

The project demonstrates the importance of a dependable predictive monitoring system in not just resolving immediate issues but enabling a secure and profitable operation for wind energy assets. By adopting a data driven approach, the owner-operator is now able to focus visual inspections on validating and managing known issues instead of investing time and expense into manual checks across an entire fleet. This method provides actionable data insights which permit reduced asset downtime while increasing turbine productivity.

A proactive approach to maintenance

By enabling early fault detection and reducing the need for manual inspections, predictive maintenance not only addresses immediate maintenance issues but also ensures long-term operational integrity and financial stability for wind energy assets. As the industry advances, investing in dependable monitoring systems is essential for safeguarding the future of renewable energy infrastructure and supporting the growing wind sector.