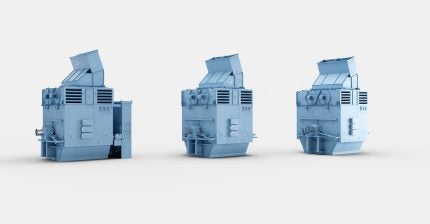

ABB has developed its new 20 MW class synchronous generator, designated ‘Modular’, as a flexible, scalable approach to balancing power grids as they cope with increasing volumes of renewable energy. In contrast to previous designs intended for continuous output only, the modular platform can be configured for various operational profiles. These range from short-term, peak shaving, through intermediate operation to traditional, continuous baseload generation. The new generator also offers the capability to increase the inertia available by incorporating flywheels.

Generating sets often need to meet country-specific grid code requirements before they may be connected to electricity networks and the Modular unit comes fully grid-code compliant. Another demanding requirement is to stay connected during a low voltage or short-circuit event in some part of the grid. This calls for high inertia to ensure that the plant stays synchronised with the grid when the fault is cleared, and voltage returns to nominal. To support this requirement, the unit has an option to add inertia by incorporating additional flywheels.

Modular construction, together with ABB’s extensive global supply chain, enables the new generator to be delivered within shortened timescales. It is also designed to support easy transportation and installation

Using the Modular synchronous generator in peak-shaving or intermittent operational profiles typically means that the running hours are shorter compared to traditional continuous operation. This reduces the demand for cooling. Therefore, the new design also features an upgraded cooling unit which can be operated only as needed.